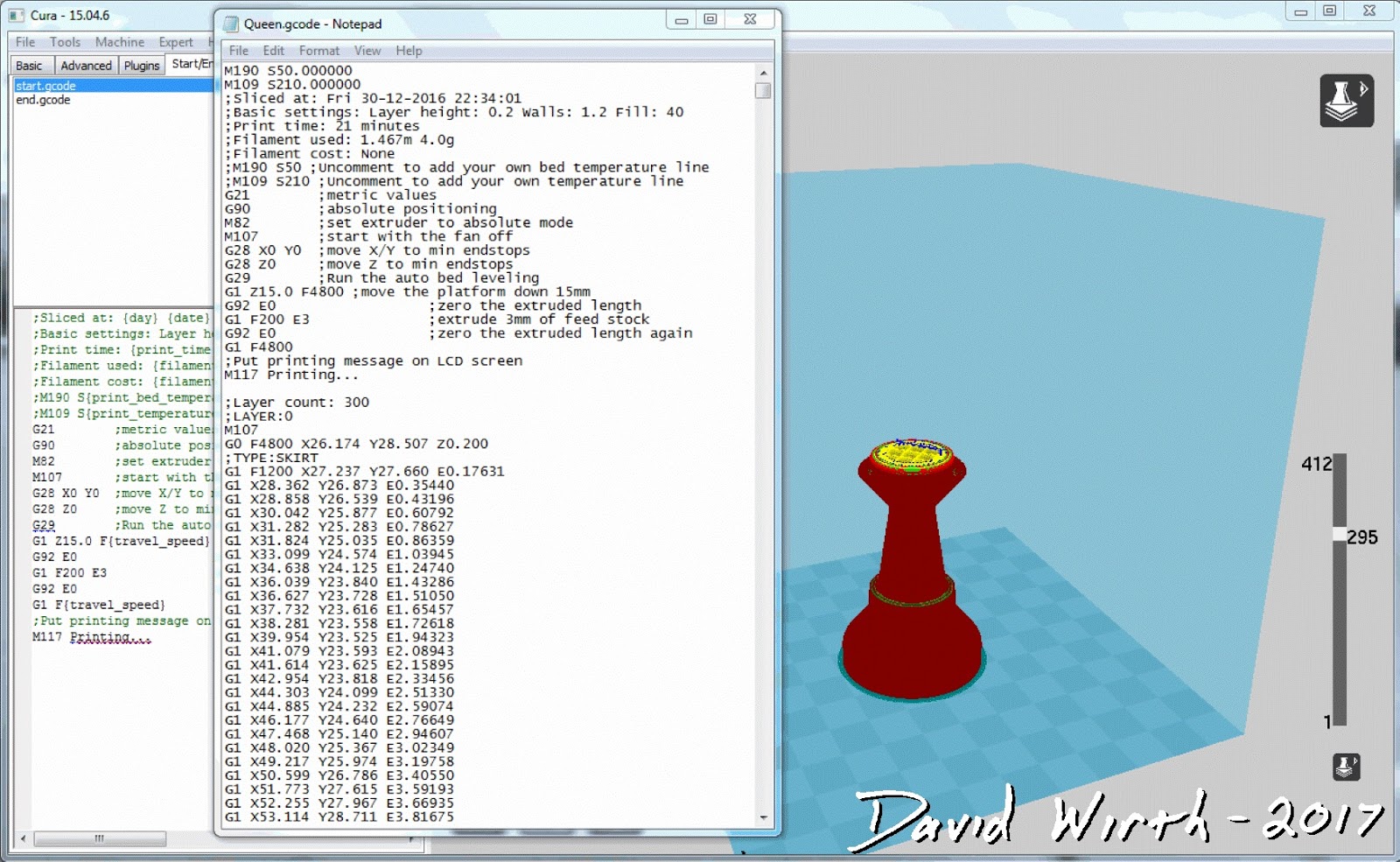

The popular slicer software usually has an ability to create profiles for the 3rd party 3D printers, even those not listed in the pre-set selection. But it will be a waste of an opportunity not to dig in further and not to learn more about the advanced settings or not to try some of the sophisticated features. When using such software for 3D printing a basic non-challenging model, an operator needs to do nothing apart from pressing the button to slice the model and save the file as G-code.

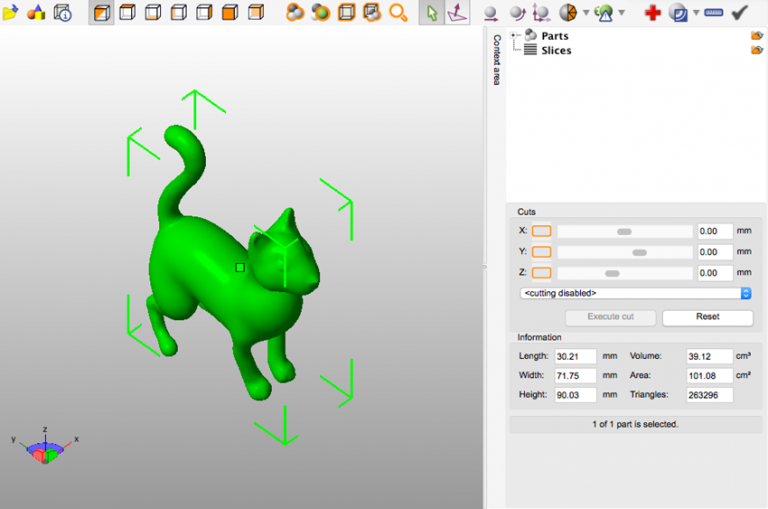

There are slicers that help to make 3D printing experience beginner-friendly with some basic straight-to-action functionalities. Plainly speaking, slicers tell 3D printers what to do. This is done by setting a lot of parameters, such as the nozzle movement coordinates, temperature, speed, flow rate, etc. A lot of features were contributed via GitHub by its community and various manufacturers’ R&D teams.Ī slicer, or slicing software, in 3D printing configures the files, commonly STL, to the format that 3D printers can read, G-Codes. Thanks to the open-source movement, such slicers benefit from new features very quickly, but at the same time, it is difficult for us to give credit to the developers.

0 kommentar(er)

0 kommentar(er)